Online OSHA 30 Training in Connecticut for Workers and Supervisors

OSHA 30 training has become an important qualification for workers and supervisors across Connecticut...

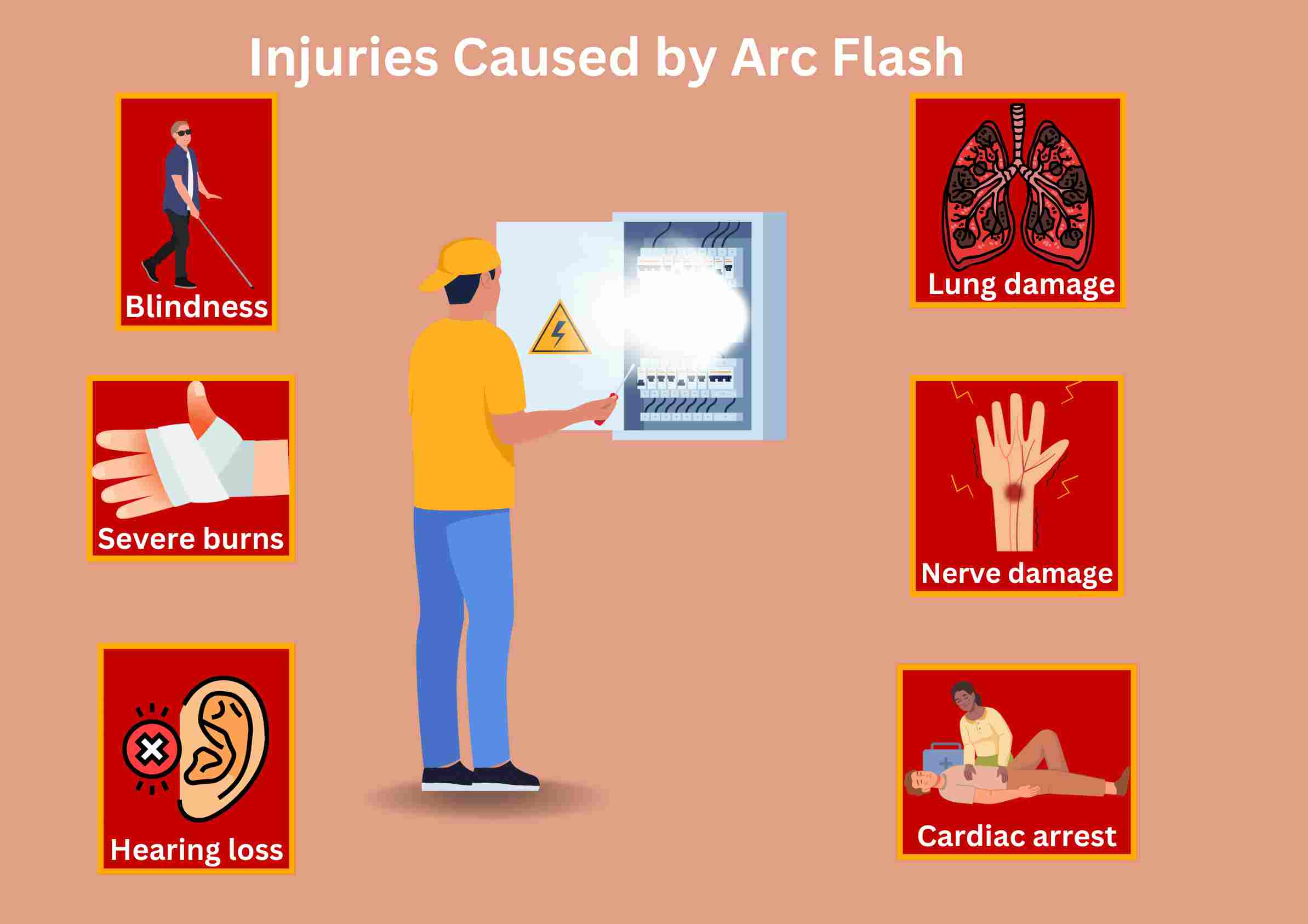

Working with electrical equipment comes with serious hazards, one of these hazards is an electrical explosion called arc flash. It occurs due to the sudden release of energy caused by a fault or short circuit in an electrical system. This electrical energy is released as intense heat, sound, and bright light that can cause fires, burns, severe injuries, or even death. According to ESFI, every year 2000 workers are affected by severe arc flash burns and admitted to burns centers for treatment. Proper training of workers about the installation of materials, wearing the right protective gear, and regular maintenance can avoid incidents and make the workplace safe.

Following are some causes of arc flash that may result in incidents. Workers need to be aware of how to prevent hazards associated with these situations.

Dust: Excessive dust around the electrical equipment can lead to ignition risks. Dust accumulation may create a conducive environment for electrical arcs, as it can catch fire and make an arc flash incident more severe. Regular cleaning and maintenance of the electrical equipment can minimize the risk of incidents.

Electrical Equipment Failure: One of the reasons for arc flash incidents is the failure of electrical equipment. When equipment malfunctions or breaks down, it can result in a sudden discharge of energy known as an arc flash. Using high-quality components and timely inspection contributes to a safe working environment.

Corrosion: The slow breakdown of metal due to corrosion can undermine the effectiveness of conductive metals, increasing the risk of electrical faults and contributing to the incidence of an arc flash. To mitigate the risk associated with corrosion, it is imperative to use corrosion-resistant materials and conduct regular inspections of the electrical systems.

Human Error: Mistakes or oversights during electrical work, such as improper maintenance procedures, mishandling equipment, or not following safety protocols, might lead to an arc flash. Proper training, following safety rules, and paying attention to tasks are important measures to make electrical operations safe.

Accidental Contact: Unintentional touching or coming into contact with energized parts or tools during electrical work can lead to the release of energy in the form of an arc flash. This can happen when workers don’t follow safety guidelines.

Certain factors causing arc flash can’t be controlled by people. However, several safety measures can be implemented to prevent accidents and improve safety. Following are some preventive measures for arc flash.

Arc Flash Risk Assessment: Preventing arc flash starts with careful risk assessment. This includes identifying hazards within the electrical system, checking equipment conditions, and categorizing risk levels. Use incident energy analysis to choose the right safety gear (PPE) and set up safe ways to do tasks. Documenting the results of the risk assessment and regularly reviewing them keeps everything safe and up-to-date.

De-Energize Electrical Equipment: Avoiding work on live electrical equipment can keep workers safe from potential harm. This process involves isolating and disconnecting the equipment from the power source. Before performing maintenance or repairs, workers should use lockout and tagout devices to secure the equipment for a safer environment.

Personal Protective Equipment (PPE): Wearing personal protective equipment (PPE) is a pivotal preventive measure against arc flash. It functions as a safety shield, not only reducing the risk of injuries but also providing protection from potential hazards related to arc flash incidents. It is important for workers to undergo proper training to learn how to use PPE correctly and handle electrical tasks safely.

Safety Training: Individuals working with electrical systems need to undergo Electric Arc Flash Awareness Training to understand the risks and safety protocols. This training helps individuals to prioritize safety and mitigate the risks of incidents linked to arc flash.

To prevent OSHA citations and keep workers safe from incidents, it is important to provide proper training, increase awareness about electrical hazards, and supply the right protective gear (PPE). These measures help to reduce accidents and make a safe working environment for electrical operations.

OSHA 30 training has become an important qualification for workers and supervisors across Connecticut...

A fatal incident at a Kansas plastics plant shows how ignoring basic safety procedures can cost a life. At Great...

Alabama’s construction, manufacturing, transportation, and general industry sectors play a major...

If someone works on state-funded construction projects in Connecticut, they have likely heard about OSHA 10...

Let's be honest: Substance abuse is a big issue that doesn't just affect the individual. When it enters the...

Heat stress remains one of the most overlooked hazards on construction sites. Roofers, road crews, landscapers, and many outdoor workers...